Share an article about the neon light installation process

Time:2020-03-04

Views:182

1. Measure according to the requirements of the design drawings and site conditions. Positioning and laying out will determine the brackets for fixing lamps and transformers. If pre-embedded iron parts are required, they should be pre-embedded in conjunction with civil engineering, or the iron parts should be marked on the civil engineering drawings and buried by civil engineering.

2. Bracket production and installation

(1) Neon tube bracket: generally made of section steel into a frame. The bracket is made according to the size of the neon lamp. The frame should be made by design. The frame should be firm and beautiful. Outdoor should be resistant to wind pressure and corrosion. Before installation, it should be brushed twice to prevent rust. The lacquer fixes the bracket on the embedded part, which can be welded by electric welding; if the iron part is not embedded, it can be fixed by expansion bolts, but the strength requirements must be met, and the design should be given opinions.

(2) Transformer bracket: The neon light transformer should be installed as close to the tube as possible to shorten the high-voltage wiring. The height of the outdoor installation transformer should not be less than 3m, and guardrails should be added. The transformer installation should be placed in a metal box, and both sides of the box should be opened. Louvre windows should be ventilated and heat-dissipated, and rain-proof measures should be taken. Shaped steel should be used as support according to the actual situation of the metal box. The support can be installed on the wall, roof, or on the concrete pier, but it must be firm and reliable.

3. Lamp production and assembly

Neon tubes are generally made of glass tubes with a diameter of 10-20mm, which are first staked out and bent. An electrode is installed at both ends of the lamp tube. After the glass tube is evacuated, it is filled with inert gas such as neon and helium as the luminescent medium. High voltage is applied to both ends of the electrode. The electrode emits electrons to excite the inert gas in the tube to make the current flow. The light tube emits light beams of different colors such as red, green, blue, yellow, and white. Table 21.3.2.3.a is the relationship table of color, gas and glass tube color.

The ionized gas of a neon tube is conductive in vacuum, and the resistance is related to the diameter and length of the tube, and determines the current and voltage required for the lamp to start. Table 21.3.2.3.b is the tube diameter and luminous efficiency relationship.

4. Installation of lamps and transformers

(1) Neon lamp tube installation: The lamp tube installation is fixed with a special insulating bracket or fixed with various insulating supports made of glass, porcelain or plastic. Some can be tied tightly with 0.5 bare copper wire. After the lamp is fixed, The distance from the surface of buildings and structures is not less than 20mm. It is installed in a place that is not easy to reach. The power supply voltage of the pipe end is high voltage. Therefore, the conductor of the neon lamp imported from the transformer for the second time should be high-voltage insulated wire with a rated voltage greater than 15kV, or bare For copper wire jacket glass protection tube, the distance between high-voltage wires and between high-voltage wires and the laying surface should not be less than 50mm; the distance between the supporting points of high-voltage wires is 0.5m when laying horizontally; when laying vertically, supporting points The distance between the two is 0.75m; when the high-voltage wire passes through the building, double-layer glass pipes should be used to strengthen the insulation. The two ends of the glass pipe must be exposed on both sides of the building, and the length is 50-80mm.

When installing a small neon tube indoors or in a shop window, tighten the galvanized iron wire covered with a transparent glass tube on the frame to form a grid with a pitch of 200-300mm, and then use Φ0.5 bare copper wire or string wire for the neon tube Tighten it with the glass tube, as shown in Figure 21.3.2.4.(1). When neon lights are installed in the window, the window door should have an interlocking device with the primary side switch of the neon light transformer to ensure that the neon light power is not turned on when the door is opened to ensure personal safety.

Figure 21.3.4. (1) Neon tube binding and fixing

1. Sectional steel frame; 2. Φ1.0 galvanized iron wire;

3. Glass sleeve; 4. Neon tube; 5. Φ0.5 copper wire tie

(2) Neon lamp transformer installation: The neon lamp special transformer adopts the double-loop type, and the length of the lamp tube provided is not greater than the allowable load length. The outdoor transformer and metal box should be firmly installed on the bracket, frame or concrete pier. The shutters of the metal box should be hung with steel mesh to prevent small animals and birds from entering and causing short circuits; the iron core, metal shell, one end of the output terminal and the protective box of the neon lamp bracket and neon lamp transformer should be reliably grounded.

(3) Neon light primary power supply: The neon light distribution circuit shall not share a circuit with other lighting equipment. For neon lights with a capacity of not more than 4kW, single-phase power supply can be used, and for large neon lights with a capacity of more than 4kW, three-phase power supply and three-phase balance should be used. Neon light control can be selected according to needs, timing switch or control switch.

The control box is generally installed in the room adjacent to the neon lights. In order to prevent the high voltage from being touched when the neon lamp is overhauled, a power control switch and a fuse should be installed between the neon lamp and the control box. When the lamp is overhauled, the control box switch should be disconnected first and then the on-site control switch to prevent errors. Danger of electrifying the neon tube by closing.

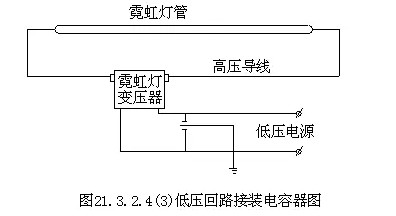

After the neon lamp is energized, high-frequency noise waves will be generated in the tube, which will radiate to the surrounding of the neon lamp and seriously interfere with the normal use of the TV and radio. In order to avoid this situation, a suitable capacitor can be connected to the low-voltage circuit to achieve the goal. As shown in Figure 21.3.2.4.(3).

5. Debugging and trial operation

Debugging should be made to check whether the control switch meets the design or user requirements, and can meet the design purpose and user requirements. It should be operated continuously for 24 hours and recorded every 2 hours. No abnormalities can be organized for acceptance.

Brands:RayNeon® RAYTA®

Brands:RayNeon® RAYTA®

Wechat

Wechat